RM was established in 1985 as a production project to support the parent company, OCMIS Irrigation SpA.

In the early years of our activity, we focused on the production of components for the irrigation and earth-moving sector. The expansion into third-party mechanical processing and the production of hydraulic cylinders was a natural evolution of our journey.

Today, we are a precision mechanics company with a comprehensive offering, combining design consulting with the production of prototypes and small-scale high-value batches..

Specialized in being cross-functional, the business areas.

Our design and manufacturing capabilities are directed towards multiple sectors, each of which presents different applications.

Prototypes and complex batches "made in RM" are the response to the needs of various sectors, including:

- AUTOMOTIVE

- AGRICULTURE AND IRRIGATION

- MACHINE TOOLS

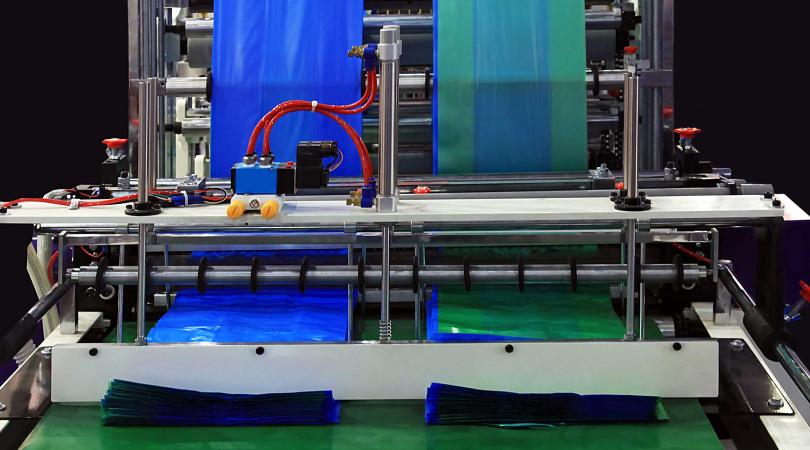

- PACKAGING INDUSTRY

- ENERGY

- LIFTING AND HANDLING EQUIPMENT

- PRESSES STEEL INDUSTRY

RM's strategy is built on autonomy and internal skills, focusing on investments in areas that deliver the best results. When addressing market demands, we prefer to adopt a collaborative approach that highlights the company's strong suits, such as the quality and skills of our people and investments in new machinery.

This approach has proven to be successful, as evidenced by the consistent improvement in efficiency and productivity, as well as the development of enduring customer relationships.

RM's essence

Balance between machine technology and human expertise.

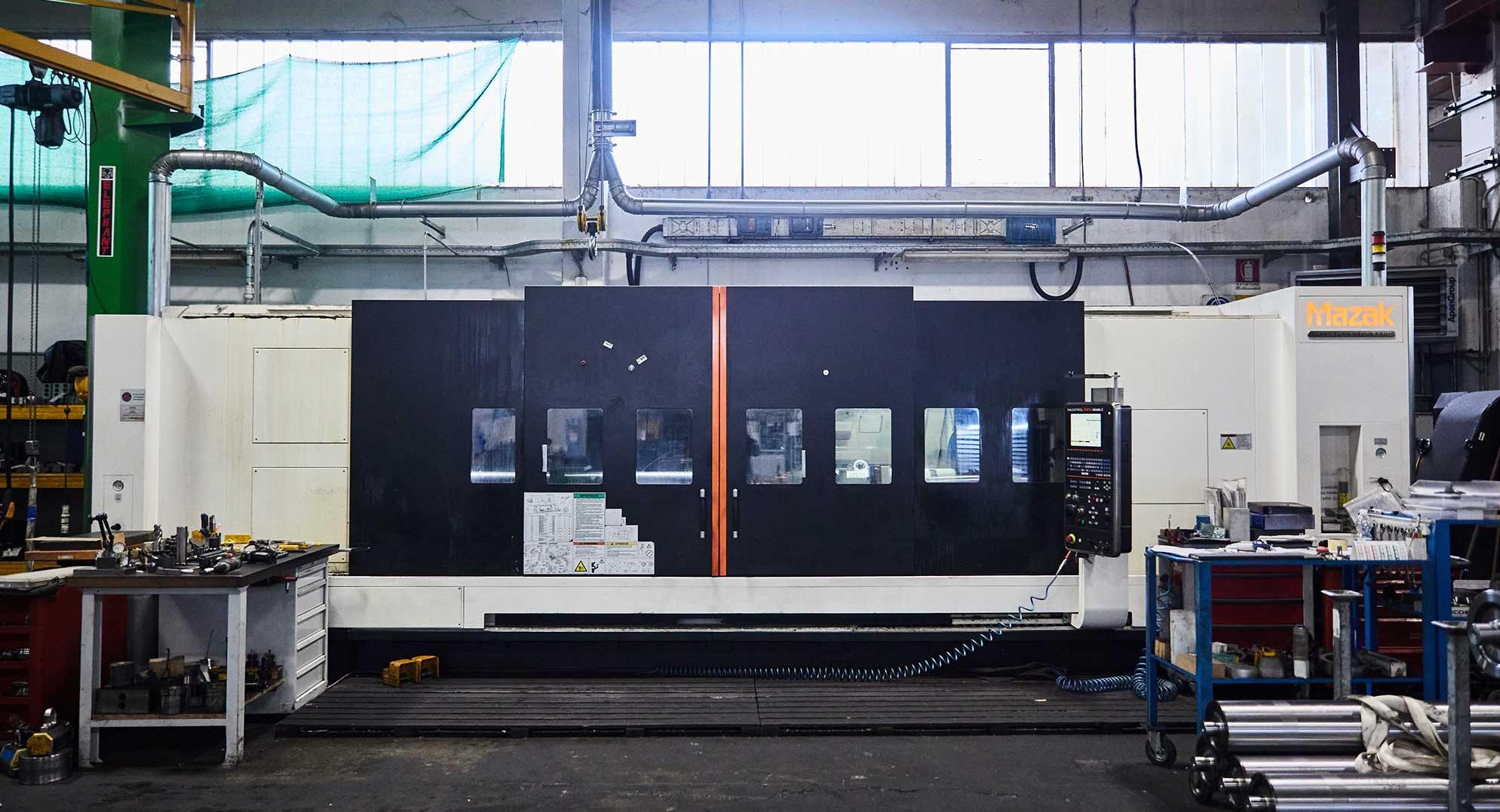

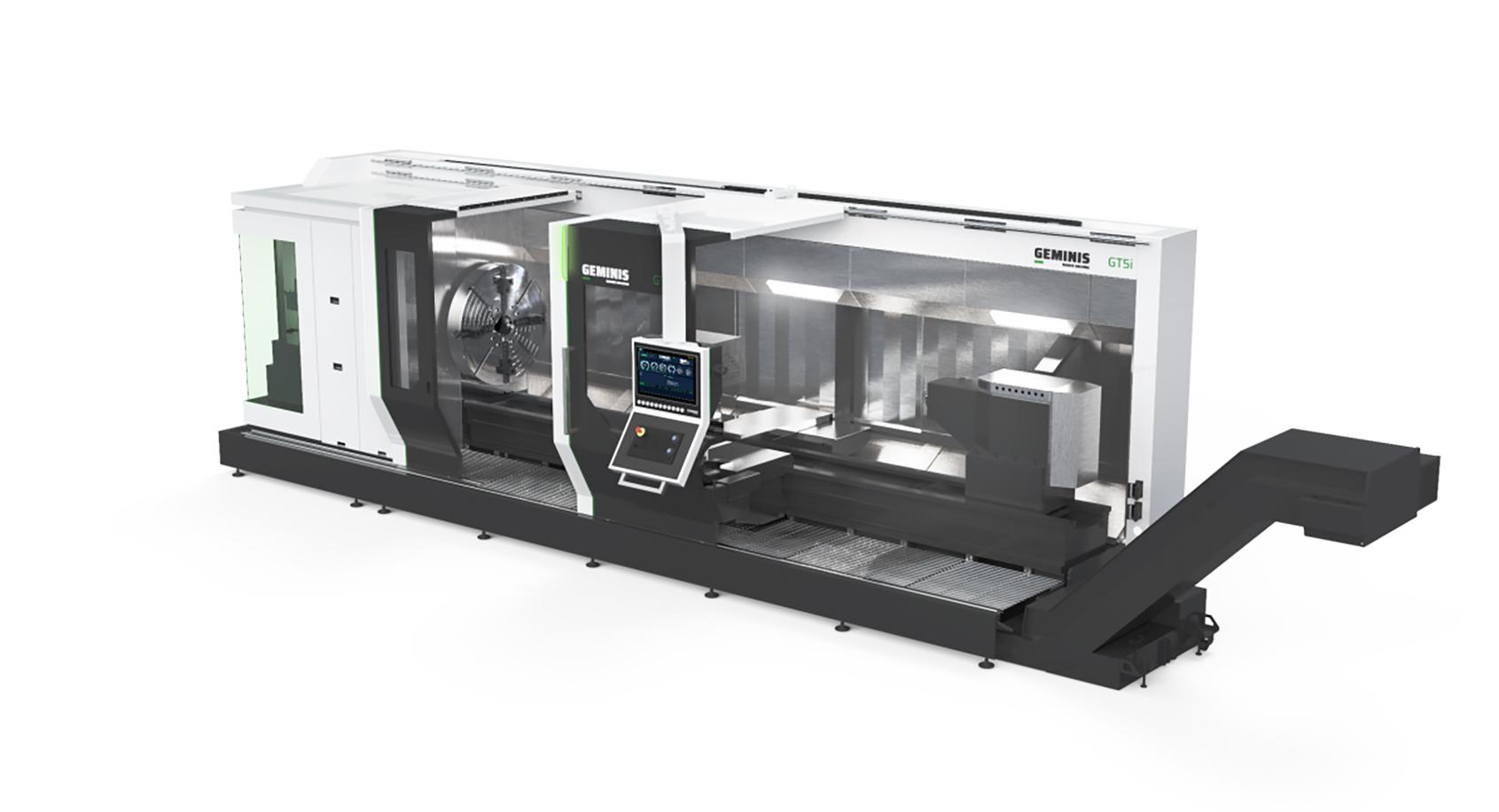

Investing in state-of-the-art machinery and innovative technologies is essential to ensure high-quality service. Equally important is the expertise of the people working in the company. It is only through their experience and skills that the full potential of the machinery can be realised, and innovative solutions can be found for daily challenges. Finding the right balance between technology and expertise represents a key success factor for those who, like us, are operating in the mechanical industry.

Being third-party contractors, we express our capabilities along specific directions.

-

Training and investment

Machines set standards, and so do the people who know how to use them. Training at RM is just as important as investments in facilities.

-

The technical office is a distinguishing factor

The presence of a structured technical office provides support and consultation from the early stages of projects, facilitating the manufacturing of prototypes and small-scale batches.

-

Complete control of the process

What we do, we do internally. Only a few marginal processes are carried out by accredited external partners.

-

Open-mindedness to new sectors of application and markets

Diversification means engaging with new realities and needs, there is always something valuable to learn. We explore markets beyond borders because the international scene is qualifying, creating a balance with the domestic market.

Mechanics is an eternal apprenticeship. Just when you think you have achieved an optimal result, it's time to roll up your sleeves again. Perfection is a never-ending journey.

Our promise

We are down-to-earth people and our hands are always busy.

But we are aware of our production and organization responsibilities and we look towards our territory and the community in which we operate. We work towards a future where the mechanical industry, including our company, can play an increasingly important role in creating quality jobs and offering opportunities to the younger generation.

Designing and manufacturing hydraulic cylinders and mechanical components is our job. Carrying it out while ensuring a balance between profitability, technological innovation, and care for people is our daily mission.

-

Transparency

For RM, it is important to establish long-lasting and transparent relationships. In general, we expect the same level of transparency from our counterparts, regardless of their role.

-

Respect and Trust

We always give both, first. They are the key to building clear and long-lasting relationships, enabling us to establish healthy working relationships with external partners and create a balanced and high-quality work environment within the company.

-

Quality and Reliability

In RM's work, the certainty of repeatability is fundamental, it is the true unwritten certificate of quality that everyone can perceive. Consistency in organization is a characteristic that reflects in the production as well as in every other aspect of the company's life.

-

Quality

Quality of the work, quality in Interpersonal relationships, quality in strategic decisions. In RM quality Is palpable, genuine and sincere.

-

Value of People

RM adopts meritocratic criteria to guarantee fair professional growth for all employees. The company is committed to creating a welcoming work environment where the individual is at the centre, not just a mere resource. The human and personal dimension is always prioritised.

Cleaner mechanics through renewable energy

RM has taken a significant step forward towards the environment and sustainability.

We have invested 300,000 euros to install a photovoltaic system to generate electricity from renewable sources. As a result, we are able to produce 228,000 kilowatt-hours of clean energy annually, thereby reducing our environmental footprint.